Tesla's 4680 is so amazing?

There is no shortage of topics in the car circle, but it has shifted from the previous "car building" to "car dismantling".

Not recently, the American engineering consulting company Munro & Associates also pulled out the star with the surname T for "rehabilitation".

In more than a month, the 4680 battery of a Model Y was disassembled. It took two weeks just to pry open the top cover of the battery... If it wasn't for a professional counterpart, there is a high probability of violent disassembly.

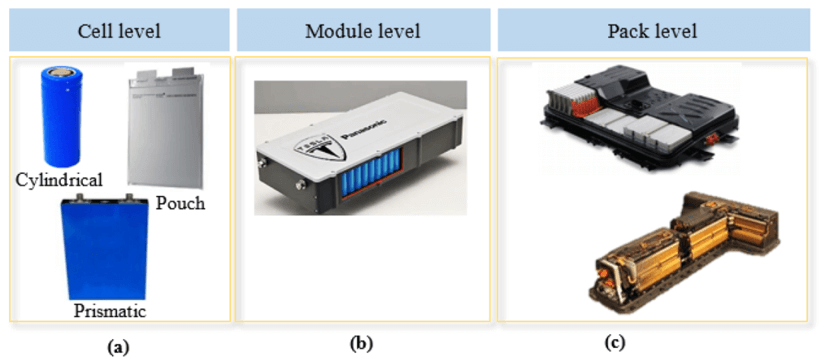

As we learned, Tesla released both 4680 cells and CTC technology in 2020. In April this year, the first batch of "4680 battery + CTC chassis" Model Y was delivered to the owner.

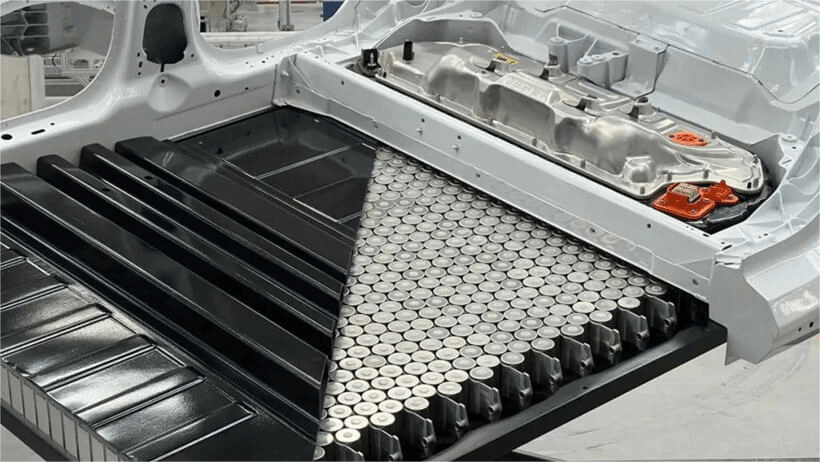

There are two main technical routes for CTC: integrating the battery pack into the vehicle chassis, indirectly replacing the floor; or directly integrating the battery cell in the chassis. Tesla is the latter, with owners almost driving on the battery.

However, the dismantling results of the 4680 battery recently released by the Sandy Munro team show that this "almost" is almost meaningless.

What do you think:

Actually:

Image credit: Munro Live video

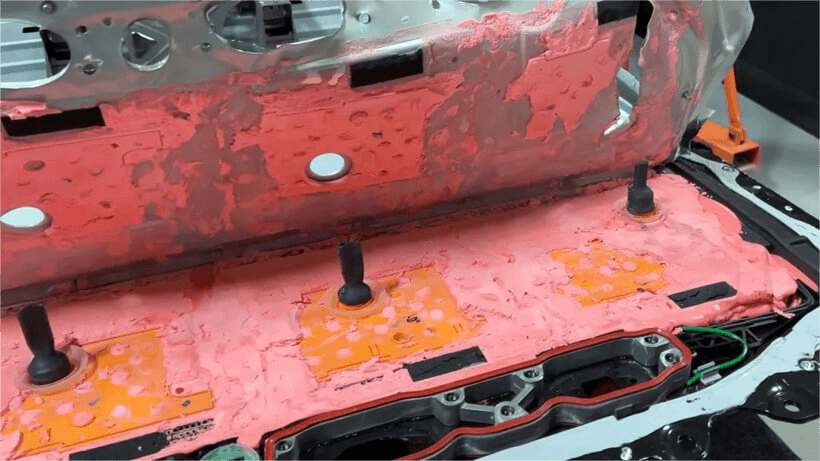

Under the battery cover, there is a pink polyurethane material covered with cells, and the thickness is not small. The secret that Tesla 4680 batteries can guarantee strength by eliminating modules and battery packs also surfaced.

Polyurethane adhesive has high viscosity and elasticity when cured, so it has good impact resistance and vibration resistance.

Compared with the metal skeleton of traditional battery packs, this type of foam material can absorb the energy of the battery force when the electric vehicle is hit, thereby reducing battery damage. Filling between cells also improves heat transfer from cells to cooling equipment, isolating overheated cells from each other and reducing the risk of fire.

Intuitively, without the fixation of the module and the battery pack, hundreds of cells are firmly glued together and will not sway on the chassis.

Polyurethane is very popular in the field of power batteries, and the early Model 3 battery consumption is still relatively small (Jack Rickard team disassembled Model 3 in 2018, and polyurethane was used to protect the sampling point of FPC flexible circuit board), but it was 4680 The hero of the battery.

But integration also means that it is not an easy task to take out all the single cells. Sandy Munro's team took advantage of industry practice of cleaning polyurethane foam with dry ice.

After one operation, the 4680 large cylindrical battery finally revealed its true colors.

The top layer of the cover plate integrates the wiring harness of the voltage and temperature sampling sensors, and the next layer is to connect the cells into a series-parallel current collector.

Consistent with the previously exposed patent diagram, due to the increased current passing through the 4680 cell, the aluminum wire welding process used in the previous generation 2170 battery pack is no longer applicable, but instead the busbar laser welding (Busbar) is used. Connect the single cells.

Busbar has the title of "electrical connection bridge of battery cells" and is an important helper for the safety of power batteries.

In addition, another interesting discovery during the dismantling process is that a total of 828 cells are loaded on the Model Y chassis, which are separated by three resin-based insulating materials. Musk has previously said that the 4680 battery "completely cancels the traditional module", but this design is more like a concession made by abandoning the traditional physical partition.

Because at present, heat dissipation and thermal runaway risk are still the two major factors surrounding the design of power batteries.

For example, in the BYD Yuan EV dismantled by Haitong before, the interior of the battery pack of the car uses an asbestos thermal insulation pad as a barrier protection. In this regard, polyurethane is indeed a progressive material.

However, the design of the entire battery cell on the vehicle chassis is simplified, the technology is more advanced, and the integration level is higher. From the perspective of maintenance, it is even more difficult.

As a former Ford engineer, Sandy Munro felt that the possibility of repairing the 4680 battery was almost zero from the point of view of the glue pouring technology. Because it involves a series of processes such as gluing, re-filling, and sealing and waterproofing testing, it is not cost-effective.

This is also the dilemma faced by the "4680+CTC" technology.

The two-year-old Tesla 4680 battery has experienced the embarrassment of going from a much-anticipated C-position debut to becoming a "capacity purgatory", and considering the fact that it is impossible to repair, its production process is destined to be extremely harsh.

Replacing the entire battery chassis would certainly cost a fortune. A similar accident occurred earlier this month. The owner of a certain brand of car accidentally crashed while driving and had to replace the battery pack. The repair cost was less than half of the billing cost.

The cost of replacing the entire battery pack for some domestic models is almost half of the cost of the car, which sounds very sad. Of course, if it can be recycled and purchased, the owner will not be too panicked psychologically.

Musk has said before that the 4680 battery recycling is definitely no problem. However, there is still no unified standard in China. Although BYD, Geely and other car companies are promoting the cascade utilization of retired batteries, and some car companies support third-party recycling, the entire market is still in the stage of brutal growth, and car owners are more often hated Iron is not steel.

At the recent World New Energy Vehicle Conference, Zeng Yuqun, chairman of CATL, made a speech, suggesting that the battery recycling policy should be improved. Car owners really need it, and it is also really necessary to fully push electric vehicles.

And Tesla's 4680 battery may also be waiting.

© Copyright: هوا جي All Rights Reserved. sitemap.html | sitemap.xml | شروط الخدمة | شروط الخصوصية